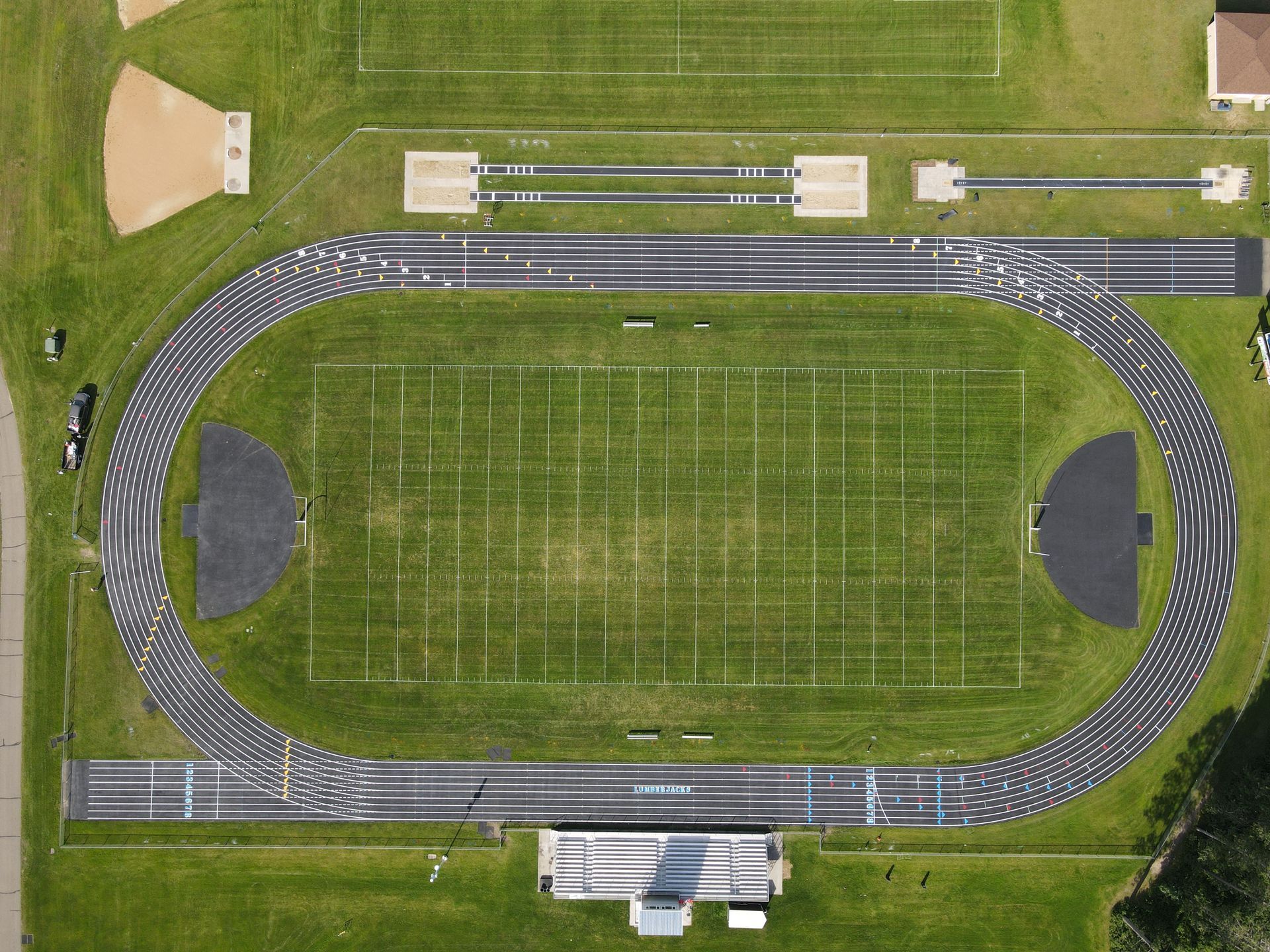

Running Tracks

All-Weather Running Track Installation & Resurfacing

Upgrade Your Athletic Track for Safer, Top-Performance Results

Our Complete Track Surfacing Services:

- New All-Weather Running Track Installation

- Resurfacing & Repair of Existing Tracks

- Asphalt Track Sealing

- Professional Striping

- Annual Maintenance & Crack Filling

- And More!

Keep Your Track in Top Shape: Routine maintenance, including crack repair and resurfacing, is essential to prevent injuries and extend the life of your track. Most facilities require resurfacing every 5–10 years—don’t wait until small issues become costly repairs.

Book Your Free Site Assessment

Reserve your project slot, summer installation schedules fill fast!

Frequently Asked Questions

Is your running track due for an upgrade, repair, or routine maintenance?

JB Surfaces specializes in installing and resurfacing all-weather running tracks that balance elite performance with athlete safety—serving schools, universities, and sports facilities across North Dakota, Minnesota, and South Dakota.

What are the common issues that running tracks develop over time?

Yearly maintenance should consist of filling cracks and repairing areas that may have been scraped off or delaminated. Over time, running tracks naturally face wear and tear from frequent use and changing weather conditions. To keep your track in optimal shape and extend its lifespan, it’s important to address common issues such as:

- Cracking

- Surface fading and color loss

- Worn or peeling surface coatings

- Hardening or roughness of the track surface

- Improper drainage

- Line fading or chipping

By staying on top of these routine repairs, you’ll help ensure your track remains safe, visually appealing, and comfortable for athletes.

How does resurfacing extend the lifespan of a running track?

Yearly maintenance should consist of filling cracks and repairing areas that may have been scraped off or delaminated. Under normal use, re-surfacing with additional rubber and binder is required every 5-10 years.

Resurfacing isn’t just an expense—it’s a long-term investment in your facility. By keeping up with routine repairs and scheduled resurfacing, you’ll extend your track’s lifespan, reduce future maintenance needs, and maintain a safe, high-performance surface for athletes.

In addition to our installation and repair services, we offer preventive maintenance strategies to help you catch wear and tear before it becomes a bigger issue. Our team provides warranty coverage for both materials and installation, plus performance monitoring and touch-up options designed to keep your track in peak condition year-round.

What results and benefits can be expected from professional track resurfacing?

A Plexitrac all-weather running track surface installed by JB Surfaces can provide increased resilience while maintaining the perfect balance between the performance desired and the cushioning needed for the athlete’s safety.

Not only do we install new all-weather surfacing, but we also offer services for repairing and resurfacing your existing track.

Yearly maintenance should consist of filling cracks and repairing areas that may have been scraped off or delaminated. Under normal use, re-surfacing with additional rubber and binder is required every 5-10 years.

With a surface supplied and installed by JB Surfaces, you can trust that experienced, qualified people are performing the work and that only reputable products are used. Our supplier of Plexitrac surfacing material, California Sports Surfaces, has proprietary poly resin binders offering superior performance, allowing us to provide a durable surface at an affordable price.

Why do schools and athletic facilities choose certain track resurfacing contractors?

A Plexitrac all-weather running track surface installed by JB Surfaces can provide increased resilience while maintaining the perfect balance between the performance desired and the cushioning needed for the athlete’s safety.

Not only do we install new all-weather surfacing, but we also offer services for repairing and resurfacing your existing track.

Yearly maintenance should consist of filling cracks and repairing areas that may have been scraped off or delaminated. Under normal use, re-surfacing with additional rubber and binder is required every 5-10 years.

With a surface supplied and installed by JB Surfaces, you can trust that experienced, qualified people are performing the work and that only reputable products are used. Our supplier of Plexitrac surfacing material, California Sports Surfaces, has proprietary poly resin binders offering superior performance, allowing us to provide a durable surface at an affordable price.

Why Choose JB Surfaces for Your Track Project?

Proven Expertise

Our team brings a track record of hundreds of successful resurfacing projects across a range of climates and facility types.

Consistency & Professionalism

Every project is handled by our in-house crews—no subcontractors—ensuring accountability, consistency, and a seamless process from start to finish.

Specialized Equipment

We utilize advanced, purpose-built equipment to deliver precision results, especially on high-performance latex and poly resin track systems.

Elite, Seamless Surfaces

Our process ensures a uniform, encapsulated finish—no dry spots, no hollow sounds—so your athletes train and compete on the best possible surface.

Standards You Can Trust

As members of industry-leading organizations and suppliers, we meet or exceed educational and professional facility standards.

Whether you need a brand new all-weather surface, expert resurfacing, or prompt repairs and striping, JB Surfaces delivers quality that lasts.

Why Many High Schools, Colleges, and Organizations Choose JB Surfaces

- Proven Plexitrac surfacing by California Sports Surfaces—trusted for durability in Midwestern climates

- Installed by experienced, local professionals with a track record of excellence

- Focused on safety: advanced cushioning and resilience to protect your athletes

- Affordable, transparent pricing—no surprises

Surface Materials and Options

We offer a comprehensive selection of running track surface materials to meet the needs of every facility and level of competition, including:

- Rubberized Track: Provides reliable traction and comfort for athletes.

- EPDM (Ethylene Propylene Diene Monomer): A synthetic surface offering weather resistance and flexibility.

- Asphalt Track Coating: A cost-effective solution for basic track surfacing and sealing.

- Latex Bound Track: Delivers a softer surface, ideal for recreational and school-level tracks.

- Synthetic Track: Engineered for consistency, performance, and longevity.

- Patent-protected Latex Tracks: Advanced formulations for enhanced resilience and lifespan.

Custom color options are available for all surface types, allowing you to match your facility’s branding or create a unique look for your track. Whether you’re looking for a high-performance system for competitive events or a safe, long-lasting surface for community use, we have the right solution.

Trusted by Schools and Athletic Programs Across the Region

Join our roster of satisfied clients who rely on JB Surfaces for lasting, high-performance running tracks.

Investing in Your Facility

Resurfacing a running track is more than a routine expense—it’s an investment in your facility’s longevity and reputation. A professionally resurfaced track can add 8-10 years of life to your surface, minimize future maintenance costs, and help you avoid the far higher price tag of full reconstruction.

We offer region-specific solutions designed to last in your local climate, and we’re happy to guide you through every step—from initial budget planning to ongoing maintenance. Our comprehensive service includes preventive care programs and warranty coverage for both materials and installation, ensuring your track remains in peak condition year-round.

Whether you’re installing a new surface or revitalizing an existing one, JB Surfaces delivers results that set the pace for years to come.

Thorough, Professional Track Resurfacing

Yearly maintenance should consist of filling cracks and repairing areas that may have been scraped off or delaminated. Under normal use, re-surfacing with additional rubber and binder is required every 5-10 years.

Our experienced, qualified team uses specialized equipment and techniques to ensure your running track is smooth, safe, and ready for athletes to perform at their best. We focus on details that matter—such as proper sealing, striping, and ensuring a seamless, encapsulated finish—so your track stands up to both high-performance use and changing weather conditions.

With a surface supplied and installed by JB Surfaces, you can trust that experienced, qualified people are performing the work and that only reputable products are used. Our supplier of Plexitrac surfacing material, California Sports Surfaces, has proprietary poly resin binders offering superior performance, allowing us to provide a durable surface at an affordable price.